In the fast-paced world of manufacturing and construction, effective communication and instruction from supervisors play a crucial role in ensuring safety and efficiency. Workers at Windlock Works Inc. were recently instructed by their supervisor to bring a range of essential tools and safety gear to the job site. This directive not only highlights the importance of preparedness but also underscores the company’s commitment to maintaining high safety standards. In this article, we will delve into the specifics of this instruction, explore the safety measures implemented at Windlock Works Inc., and discuss the broader implications for workers in the industry.

The purpose of this article is to provide an in-depth understanding of the expectations placed upon employees at Windlock Works Inc. and the critical role that supervision plays in ensuring that these expectations are met. By examining the details surrounding the directive given to the workers, we aim to shed light on the significance of proper equipment and safety protocols in the workplace. Furthermore, we will explore how these practices can lead to improved outcomes for both employees and the organization as a whole.

As we navigate through this discussion, we will also touch upon best practices for other companies in the industry, drawing on the experience of Windlock Works Inc. as a case study. The following sections will provide a comprehensive overview of the tools and safety gear that workers were instructed to bring, the rationale behind these instructions, and the potential impact on workplace safety and productivity.

Table of Contents

During the recent instruction from their supervisor, workers at Windlock Works Inc. were advised to bring the following essential tools and safety gear:

- Hard hats to protect against falling objects

- Safety goggles to shield eyes from debris

- Gloves for hand protection

- Steel-toed boots to prevent foot injuries

- Reflective vests for visibility

- First aid kits for immediate medical assistance

These items are not only required by safety regulations but also serve to enhance the overall safety culture within the organization.

Importance of Preparedness in the Workplace

Preparedness is a vital component of workplace safety, especially in industries such as construction and manufacturing. The directive to bring specific tools and safety gear emphasizes the following points:

- Risk Mitigation: By ensuring that all workers are equipped with the necessary tools and safety gear, potential hazards can be effectively managed.

- Increased Confidence: Workers who are prepared are more likely to feel secure in their environment, which can enhance overall morale and productivity.

- Compliance with Regulations: Adhering to safety requirements is crucial for minimizing legal risks and ensuring a safe working environment.

The Role of Supervision in Safety Compliance

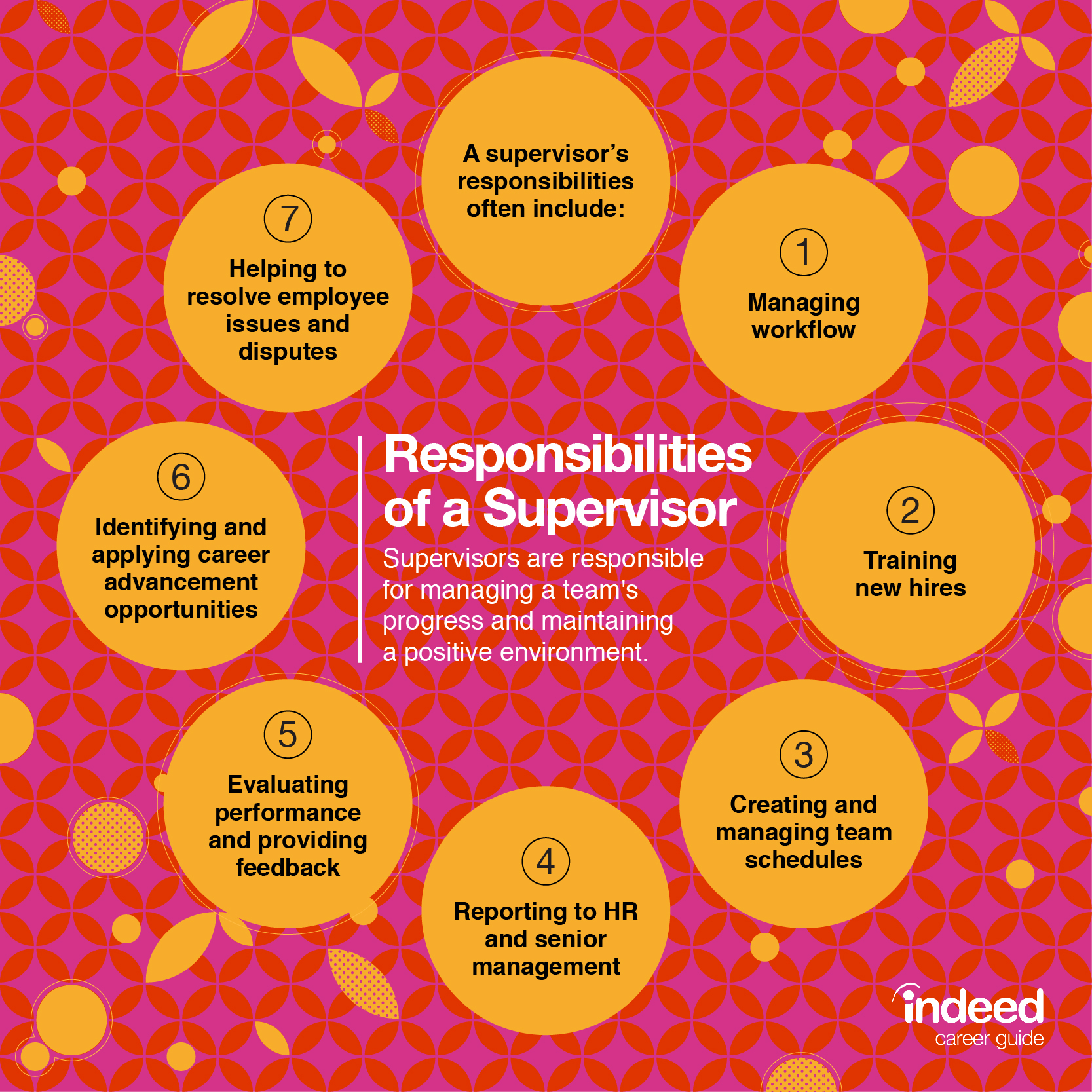

Supervisors play a critical role in maintaining safety standards in the workplace. Their responsibilities include:

- Providing clear instructions regarding safety protocols

- Ensuring that all workers are adequately trained in the use of safety equipment

- Monitoring compliance with safety regulations

At Windlock Works Inc., effective supervision has been a cornerstone of their safety culture, fostering an environment where employees feel supported and informed.

Safety Measures Implemented at Windlock Works Inc.

Windlock Works Inc. has implemented a range of safety measures to protect their employees and ensure compliance with industry standards. These measures include:

- Regular safety training sessions for all employees

- Routine inspections of tools and equipment

- Establishing a safety committee to address concerns and improve practices

These proactive steps contribute to a safer working environment and reduce the likelihood of accidents.

Industry Best Practices for Safety and Equipment

Drawing on the experience of Windlock Works Inc., several best practices can be identified for other companies in the industry:

- Regularly review and update safety protocols to align with current regulations

- Encourage open communication regarding safety concerns among workers

- Invest in high-quality safety equipment and tools

By adopting these practices, organizations can enhance safety and reduce workplace incidents.

Impact of Safety Measures on Productivity

Implementing effective safety measures has a direct impact on productivity. Companies that prioritize safety often experience:

- Reduced absenteeism due to accidents

- Higher employee morale and job satisfaction

- Decreased costs associated with workplace injuries

At Windlock Works Inc., the emphasis on safety has translated into improved productivity and a more engaged workforce.

Employee Training and Safety Awareness

Training is a vital aspect of maintaining safety in the workplace. Windlock Works Inc. invests in ongoing training programs that cover:

- Proper use of tools and equipment

- Emergency response procedures

- Awareness of potential hazards on the job site

By equipping employees with the knowledge they need, the company fosters a culture of safety and responsibility.

Conclusion

In conclusion, the instruction given to workers at Windlock Works Inc. to bring essential tools and safety gear highlights the importance of preparedness and effective supervision in workplace safety. By prioritizing safety measures, providing comprehensive training, and fostering a culture of open communication, organizations can significantly enhance their overall productivity and employee satisfaction. As we reflect on the key points discussed, we encourage readers to share their thoughts and experiences regarding workplace safety in the comments below. Additionally, feel free to explore more articles on our site for further insights.

Thank you for reading! We hope to see you back on our site for more valuable information and discussions.

ncG1vNJzZmivp6x7rLHLpbCmp5%2Bnsm%2BvzqZmm6efqMFuxc6uqWarlaR8uLvRpJyrq12WwW7DyKebpaeToHq4u9Gkqmahnph6uLHRnmSipqOpv7av056bZpqpYsGpscirZKytoJq%2Ft7XSqKlmrJ9ir7O1zaBloaydoQ%3D%3D