Understanding the dynamics of high head pressure in hermetic systems is crucial for maintaining efficiency and preventing system failures. In refrigeration and air conditioning systems, the interplay between oil and refrigerant is vital for optimal performance. This article delves into the causes and effects of high head pressure, how it impacts oil and refrigerant within hermetic systems, and the solutions to mitigate these issues. By understanding these factors, technicians and engineers can ensure better reliability and longevity of refrigeration systems.

The hermetic system, often used in refrigeration and air conditioning, is designed to house the compressor, motor, and other essential components in a sealed environment. This design minimizes the risk of leaks and contamination, but it also means that any issues, such as high head pressure, can lead to significant operational challenges. When head pressure rises beyond acceptable levels, it can cause a cascade of problems, particularly concerning the oil and refrigerant balance within the system.

In this comprehensive guide, we will explore the causes of high head pressure, its effects on oil and refrigerant, and the best practices for diagnosis and resolution. Whether you're a seasoned technician or a newcomer to the field, this article aims to enhance your understanding of this critical aspect of hermetic systems.

Table of Contents

Understanding High Head Pressure

High head pressure refers to an increase in pressure in the condenser side of a refrigeration system, which can lead to various operational issues. Understanding the implications of high head pressure is crucial for anyone working with hermetic systems.

What is a Hermetic System?

A hermetic system is a type of refrigeration system where the compressor and motor are sealed within a single unit. This design prevents the introduction of contaminants and minimizes refrigerant loss. However, it also means that any internal pressure issues can have severe consequences on system performance.

The Role of Refrigerant and Oil

In a refrigeration system, refrigerant is the fluid responsible for transferring heat, while oil lubricates the compressor and other moving parts. The balance between these two elements is critical. High head pressure can disrupt this balance, leading to inefficient operation and potential equipment damage.

Causes of High Head Pressure

There are several factors that can contribute to high head pressure in hermetic systems. Understanding these causes helps in diagnosing and resolving issues effectively.

- Overcharging of Refrigerant: Adding too much refrigerant can increase pressure levels beyond the designed limits.

- Condenser Issues: Dirty or blocked condenser coils can impede heat dissipation, leading to higher pressures.

- Ambient Temperature: High outdoor temperatures can elevate head pressure, especially in systems not designed for extreme conditions.

- Improper Refrigerant Type: Using the wrong type of refrigerant can cause mismatches in pressure and temperature characteristics.

Effects on Oil and Refrigerant

High head pressure can significantly impact both oil and refrigerant within a hermetic system. Understanding these effects is crucial for maintaining system integrity.

Impact on Oil

When head pressure increases, it can lead to oil foaming and improper lubrication of compressor components, resulting in:

- Poor compressor performance

- Increased wear and tear on components

- Potential compressor failure

Impact on Refrigerant

High head pressure affects refrigerant flow and can lead to:

- Reduced cooling efficiency

- Increased energy consumption

- Potential refrigerant leaks due to excessive pressure

Diagnosing High Head Pressure

Diagnosing high head pressure involves several steps to accurately identify the underlying issues. Proper diagnostic techniques are essential for effective resolution.

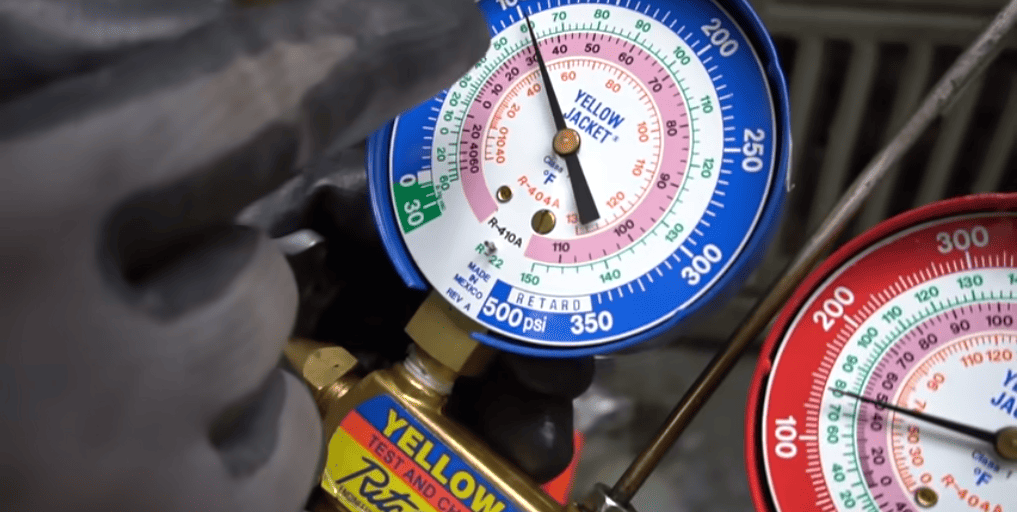

- Measure Head Pressure: Use pressure gauges to assess the head pressure levels in the system.

- Check Refrigerant Charge: Verify the refrigerant level to ensure it is within the manufacturer's specifications.

- Inspect Condenser Coils: Examine the coils for dirt, debris, or blockages that may hinder airflow.

- Assess Ambient Conditions: Take note of outdoor temperatures and conditions that may affect system performance.

Solutions and Preventive Measures

Once high head pressure is diagnosed, implementing solutions and preventive measures is crucial to restore system functionality.

- Correct Refrigerant Charge: Remove excess refrigerant if overcharged and ensure the system is filled to the correct level.

- Clean Condenser Coils: Regularly clean the coils to maintain optimal airflow and heat exchange.

- Monitor Ambient Conditions: Consider installing shading or cooling systems to mitigate extreme outdoor temperatures.

- Regular Maintenance: Schedule routine inspections to identify potential issues before they escalate.

Best Practices for Maintenance

Regular maintenance is key to preventing high head pressure and ensuring the longevity of hermetic systems. Here are some best practices:

- Perform routine inspections of all system components.

- Keep records of refrigerant levels and maintenance activities.

- Educate staff on the importance of system maintenance and proper operational procedures.

Case Studies

Examining real-world case studies can provide valuable insights into the causes and resolutions of high head pressure in hermetic systems.

- Case Study 1: A commercial refrigeration system faced high head pressure due to blocked condenser coils, leading to increased energy consumption. Regular cleaning and maintenance resolved the issue.

- Case Study 2: An industrial hermetic system experienced compressor failure due to oil foaming from high head pressure caused by overcharging. Correcting the refrigerant levels extended the system's lifespan.

Conclusion

High head pressure in hermetic systems can cause significant issues with oil and refrigerant balance, leading to decreased efficiency and potential equipment failure. By understanding the causes, effects, and solutions, technicians can maintain system integrity and ensure optimal performance. Regular maintenance and proper diagnostic techniques are essential for preventing high head pressure. We encourage readers to share their experiences in the comments and explore more articles on refrigeration system maintenance.

Thank you for reading! We hope this article has provided you with valuable insights into managing high head pressure in hermetic systems. Be sure to return for more informative content.

ncG1vNJzZmivp6x7rLHLpbCmp5%2Bnsm%2BvzqZmm6efqMFuxc6uqWarlaR8uLTEp2ShoZedeqmxwJ1kqaqVqMC2vsRmoKdlkWK1pr7Mnquim12oxrTAxKZknJmlqLK0ec6io2aZnpl6s7HFq6CgnaKWu7V6x62kpQ%3D%3D