In the world of manufacturing and production, understanding the concepts of units completed and transferred out, units in beginning WIP, and units started is crucial for effective inventory management and financial reporting. This article aims to provide an in-depth exploration of these terms, their significance, and their impact on financial statements. By grasping these concepts, businesses can make more informed decisions and improve their operational efficiency.

As we delve into this topic, we will break down the definitions, calculations, and implications of each term. We'll also discuss how these metrics fit into the broader context of cost accounting and production management. Whether you're a student, a financial analyst, or a business owner, this guide will equip you with the knowledge you need to navigate this essential aspect of manufacturing.

So, let's embark on this journey to understand units completed and transferred out, and how they relate to units in beginning WIP and units started, ensuring you have the tools to optimize your production processes and financial reporting.

Table of Contents

Definition of Key Terms

To fully understand the concepts of units completed and transferred out, it’s essential to define the key terms involved:

Units Completed

Units completed refer to the total number of products that have been manufactured and are ready for sale during a specific period. This metric is crucial as it directly affects revenue generation and inventory levels.

Units Transferred Out

Units transferred out are those products that have moved from the production process to finished goods inventory. This indicates that the units are no longer in the work-in-process (WIP) inventory and are ready for sale or distribution.

Units in Beginning WIP

Units in beginning WIP are those products that were partially completed at the start of a new accounting period. This figure is important for understanding the starting point for production in the current period.

Units Started

Units started refers to the total number of products that have entered the production process during a specific period. This metric helps gauge production activity and capacity utilization.

Importance of Units Completed and Transferred Out

Understanding units completed and transferred out is vital for several reasons:

- Financial Accuracy: Accurate reporting of these units ensures that financial statements reflect the true state of inventory and production costs.

- Operational Efficiency: Monitoring these metrics helps identify bottlenecks in the production process and areas for improvement.

- Cost Control: By analyzing units completed and transferred out, businesses can better manage production costs and pricing strategies.

Calculating Units Completed and Transferred Out

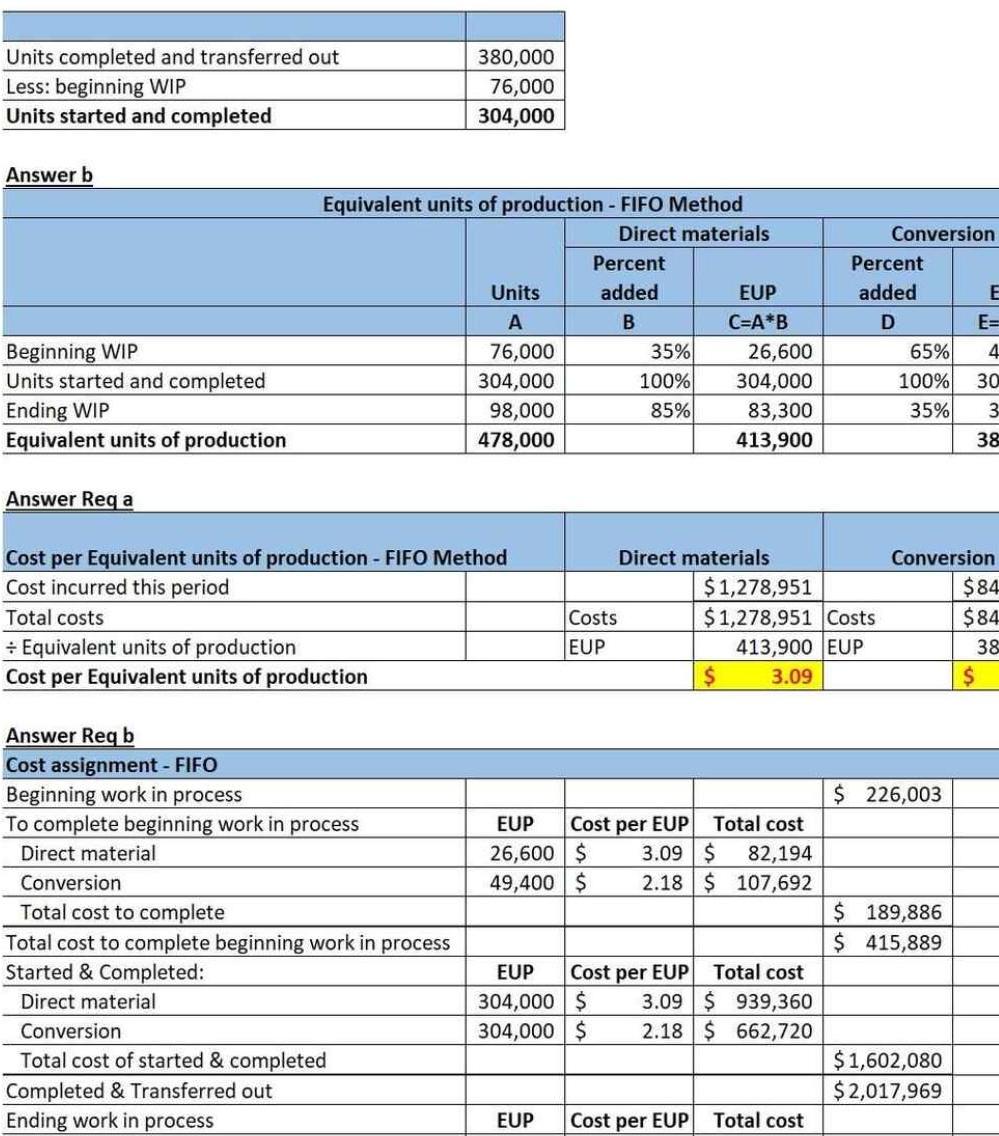

The calculation of units completed and transferred out involves a straightforward formula. To determine the units completed during a period, the following formula can be used:

Units Completed = Units in Beginning WIP + Units Started - Units in Ending WIP

Once the units completed are calculated, it is essential to identify how many of these units have been transferred out to finished goods inventory. This can usually be tracked through production reports and inventory management systems.

Impact on Financial Statements

The calculations of units completed and transferred out have a direct impact on financial statements:

- Balance Sheet: The amount of finished goods inventory is reflected in the assets section.

- Income Statement: The cost of goods sold (COGS) is influenced by the number of units completed and transferred out, affecting overall profitability.

Understanding Units in Beginning WIP

Units in beginning WIP play a critical role in production accounting. They represent the unfinished units carried over from the previous accounting period, and they affect the calculation of total units available for completion in the current period. Understanding this metric is essential for accurate forecasting and inventory management.

Units Started: What You Need to Know

Units started is a key performance indicator in manufacturing. This metric shows how many units have begun production in a specific period, providing insight into production capacity and demand management. Analyzing this data helps businesses align their production schedules with market demand.

Inventory Management Best Practices

Effective inventory management is crucial for optimizing production processes. Here are some best practices:

- Regular Audits: Conduct regular audits of inventory to ensure accuracy in reporting.

- Use Technology: Implement inventory management software to track units in real time.

- Forecast Demand: Use historical data to forecast production needs and adjust schedules accordingly.

Conclusion

In summary, understanding units completed and transferred out, alongside units in beginning WIP and units started, is essential for effective inventory management and financial reporting in manufacturing. By mastering these concepts, businesses can improve their operational efficiency, control costs, and enhance overall profitability. We encourage you to leave a comment, share this article with others, or explore related content on our site to further your understanding of these critical topics.

Thank you for reading! We look forward to welcoming you back for more insightful articles.

ncG1vNJzZmivp6x7rLHLpbCmp5%2Bnsm%2BvzqZmm6efqMFuxc6uqWarlaR8trrIrapmm5%2Biva2x056bZpmemXq1vsCnqp%2BdoqeypXnOrquuppmpwG61zWaZnp%2BZo7uqusZmrqKoXaq7qsDSZqqtmaKpsqV5zqtloaydoQ%3D%3D