In the landscape of industrialization, the introduction of interchangeable parts and the utilization of water power fundamentally transformed production processes, leading to a significant reduction in workers' hours. This innovation not only increased efficiency but also revolutionized manufacturing practices, making it easier for workers to produce goods with precision and consistency. The synergy of these two advancements played a crucial role in shaping the modern industrial era.

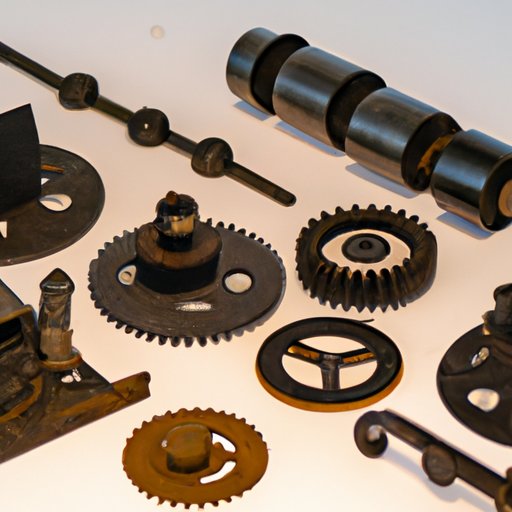

The concept of interchangeable parts, which involves creating components that are manufactured to such precision that they can be easily replaced, laid the groundwork for mass production. Coupled with water power, which harnessed the energy of flowing water to drive machinery, the industrial sector experienced a paradigm shift. As a result, factories began to operate more efficiently, allowing them to produce higher quantities of goods in shorter timeframes.

This article will delve into the historical context of interchangeable parts and water power, explore their impact on labor practices, and analyze how these innovations contributed to shorter working hours for industrial workers. By understanding these developments, we can appreciate the profound changes they brought to the workforce and the economy.

Table of Contents

History of Interchangeable Parts

The idea of interchangeable parts emerged in the late 18th century, primarily credited to Eli Whitney during the production of muskets for the U.S. military. Whitney’s innovative approach involved creating components that could be assembled without the need for custom fitting. This breakthrough led to the establishment of standardized manufacturing processes.

Before this revolution, products were often handmade, resulting in inconsistencies and requiring skilled labor for assembly. Interchangeable parts changed this dynamic, laying the foundation for mass production. Factories could now produce large quantities of identical products, significantly reducing production time and costs.

Key Developments in Interchangeable Parts

- Standardization of measurements

- Use of jigs and fixtures for assembly

- Expansion into various industries beyond firearms

Water Power in the Industrial Revolution

Water power played a critical role in powering machinery during the Industrial Revolution. By harnessing the energy of rivers and streams, factories could operate large machines that previously required manual labor. The use of waterwheels and turbines allowed for greater productivity and efficiency in manufacturing processes.

The introduction of water power not only increased production capabilities but also reduced reliance on animal and human labor, contributing to shorter working hours for factory workers. As factories became more efficient, the demand for labor shifted, allowing workers to complete their tasks in less time.

Benefits of Water Power

- Increased efficiency in manufacturing

- Reduction in operational costs

- Environmental sustainability compared to coal

Impact on Manufacturing

The combination of interchangeable parts and water power had a profound impact on manufacturing. Factories could produce goods at unprecedented rates, leading to a surplus in products available for consumers. This shift not only catered to rising demand but also stimulated economic growth.

Moreover, the precision offered by interchangeable parts ensured that products fit together seamlessly, enhancing quality and reliability. The result was a new era of consumer goods, from textiles to machinery, that were affordable and accessible to a broader population, changing the landscape of commerce.

Changes in Production Techniques

- Transition from handcrafting to mechanized production

- Introduction of assembly lines

- Emergence of specialized labor roles

Shorter Working Hours

As production processes became more efficient due to interchangeable parts and water power, workers experienced a significant reduction in working hours. Factories were able to produce the same amount of goods in less time, allowing workers to enjoy more leisure time and improving their overall quality of life.

This shift in working hours also had broader implications for society, as it allowed workers to engage in education and other pursuits outside of labor. The reduction in hours was a critical step toward improving labor rights and working conditions, leading to movements advocating for fair labor practices.

Statistics on Working Hours

- Average working hours decreased from 12-16 hours to 8-10 hours per day.

- Increased productivity led to a rise in wages for many workers.

Biography of Key Figures

Several key figures emerged during this transformative period, advocating for and implementing the changes brought about by interchangeable parts and water power. Below is a brief biography of Eli Whitney, one of the pioneers of interchangeable parts.

| Name | Eli Whitney |

|---|---|

| Born | December 8, 1765 |

| Died | January 8, 1825 |

| Known For | Inventing the cotton gin and promoting interchangeable parts |

Data and Statistics

To understand the impact of these innovations, it’s essential to analyze related data and statistics. The following points highlight key figures that illustrate the transformation in the industrial sector:

- By the early 19th century, factories using water power increased production rates by over 50%.

- Interchangeable parts reduced manufacturing time by approximately 90% for certain products.

Conclusion

In conclusion, the introduction of interchangeable parts and the utilization of water power significantly transformed the industrial landscape. These innovations not only enhanced productivity but also led to shorter working hours for industrial workers, improving their quality of life. The synergy of these advancements laid the groundwork for modern manufacturing, influencing countless industries and practices that continue to shape the economy today.

Call to Action

We invite you to share your thoughts on the impact of interchangeable parts and water power in the comments below. If you found this article informative, please consider sharing it with others who may be interested in the evolution of industrial practices. Additionally, explore our site for more engaging content on industrial history and innovations.

Thank you for visiting our site, and we hope to see you again soon!

ncG1vNJzZmivp6x7rLHLpbCmp5%2Bnsm%2BvzqZmm6efqMFuxc6uqWarlaR8qrrTnqmcoJGjtKatwaWcZqiRp8G0ecCnm2avkamys3nPqK6eql2ovG7DzquinqqjYrWwwdGsZJudk5a6pnnSoaarrJWne6nAzKU%3D