The unit cost of manufacturing an X-ray machine is a crucial factor that influences pricing, accessibility, and overall healthcare costs. As healthcare technology continues to evolve, understanding the various components that contribute to the unit cost of X-ray machines becomes essential for stakeholders in the medical field. This article aims to delve into the myriad factors influencing the unit cost of X-ray machines and provides insights into the implications for healthcare providers and patients alike.

From raw materials and labor to research and development expenses, each element plays a significant role in determining the final price tag of an X-ray machine. With rising healthcare costs, understanding these components can help healthcare facilities make informed decisions when procuring imaging equipment. This comprehensive guide will walk you through the intricacies of unit costs, offering valuable information for healthcare administrators, manufacturers, and financial planners.

Throughout this article, we will explore the various factors affecting the unit cost of X-ray machines, including technological advancements, regulatory requirements, and market dynamics. By the end of this discussion, readers will gain a well-rounded understanding of how these factors collectively influence the cost to manufacture each X-ray machine.

Table of Contents

1. The Basics of Unit Cost

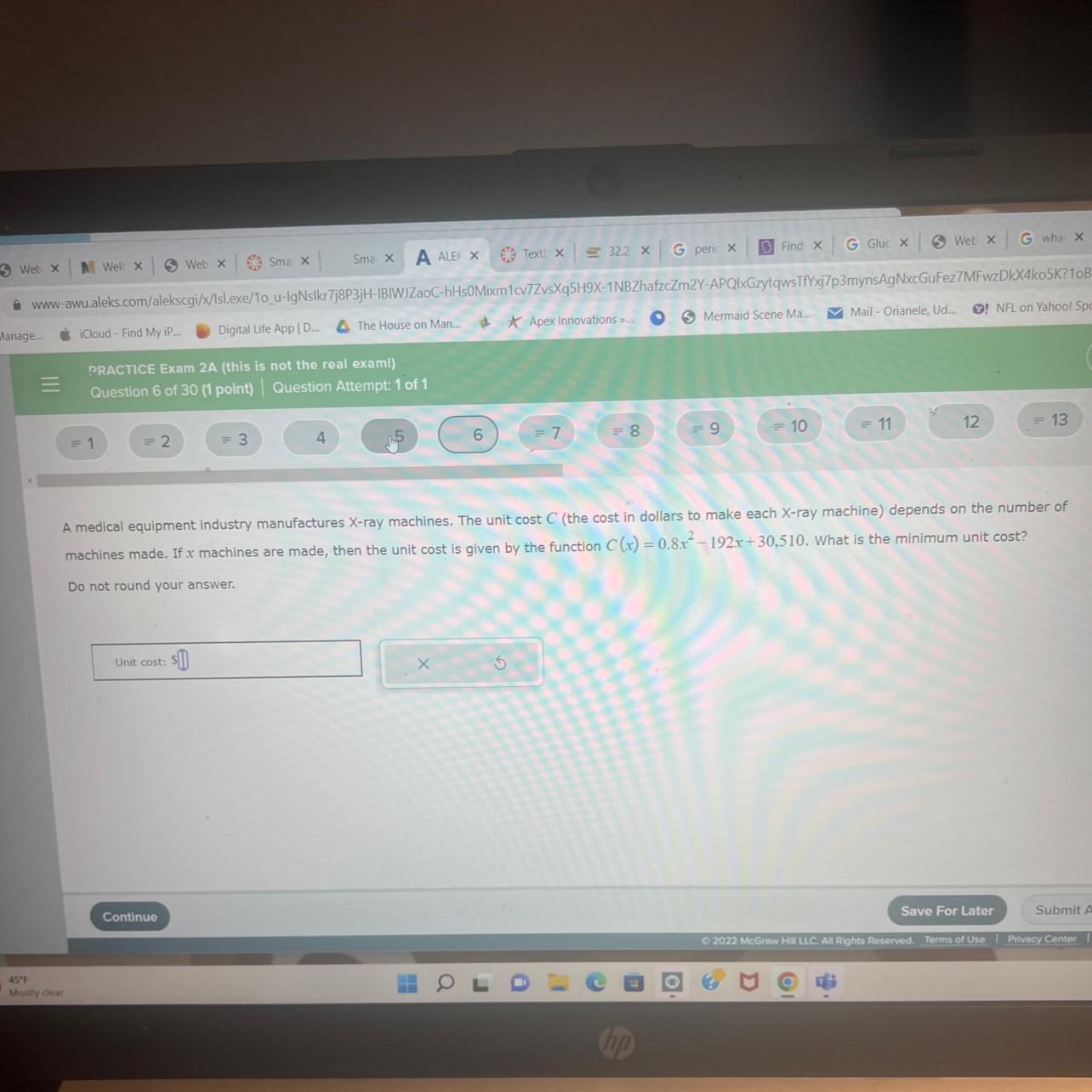

Unit cost refers to the total cost incurred to produce one unit of a product, in this case, an X-ray machine. This cost encompasses all expenses related to the manufacturing process, including materials, labor, overhead, and other indirect costs. Understanding unit cost is essential for manufacturers to set competitive pricing and for healthcare providers to evaluate the financial implications of purchasing such equipment.

2. Factors Influencing Unit Cost

Several factors play a pivotal role in determining the unit cost of X-ray machines. Below, we will explore these factors in detail.

2.1 Raw Materials

The quality and types of raw materials used significantly impact the unit cost of X-ray machines. Common materials include:

- Lead for radiation shielding

- High-quality steel for structural components

- Specialized electronics for imaging technologies

Fluctuations in the prices of these materials can cause variations in the overall unit cost, affecting manufacturers' pricing strategies.

2.2 Labor Costs

Labor costs are another critical factor in unit cost determination. This includes wages for skilled technicians, engineers, and assembly workers involved in the manufacturing process. As labor costs rise, manufacturers may need to reassess their pricing structures to maintain profitability.

2.3 Research and Development

Investments in research and development (R&D) are essential for innovation in X-ray technology. Companies that prioritize R&D may incur higher initial costs, which can be reflected in the unit cost of their machines. However, these investments can lead to improved technology and efficiency in the long run.

2.4 Regulatory Compliance

Compliance with health and safety regulations can also contribute to the unit cost. Manufacturers must ensure that their X-ray machines meet stringent standards set by regulatory bodies, which can involve additional testing, certification, and quality control processes.

3. Technological Innovations

Technological advancements can lead to more efficient manufacturing processes, potentially lowering unit costs. Innovations such as 3D printing, automation, and AI-driven design tools are transforming the way X-ray machines are produced, allowing for faster production times and reduced waste.

4. Market Dynamics

The market for X-ray machines is influenced by supply and demand dynamics. Factors such as the emergence of new competitors, changes in healthcare policies, and advancements in alternative imaging technologies can affect pricing and unit costs. Manufacturers must stay attuned to market trends to remain competitive.

5. Cost-Benefit Analysis for Healthcare Facilities

Healthcare facilities must conduct thorough cost-benefit analyses when considering the purchase of X-ray machines. Understanding the unit cost is crucial for budgeting and financial planning. Factors such as expected usage, maintenance costs, and potential reimbursement rates from insurance providers should be taken into account.

6. Future Trends in X-Ray Machine Manufacturing

Looking ahead, several trends may shape the future of X-ray machine manufacturing:

- Increased focus on sustainability and eco-friendly materials

- Integration of digital technologies for enhanced imaging capabilities

- Growing demand for portable and mobile X-ray solutions

These trends could lead to changes in unit costs and ultimately affect healthcare providers’ purchasing decisions.

7. Conclusion

In summary, the unit cost of X-ray machines is influenced by a variety of factors, including raw materials, labor costs, research and development, and regulatory compliance. Understanding these components is essential for manufacturers and healthcare providers alike. By staying informed about market dynamics and technological innovations, stakeholders can make strategic decisions that align with their financial goals.

We invite you to share your thoughts in the comments below, and feel free to explore our other articles for more insights into healthcare technology.

8. References

For a deeper understanding of the topics discussed, we recommend consulting the following sources:

- World Health Organization - Medical Equipment Guidelines

- The Journal of Medical Imaging - Advances in X-ray Technology

- Healthcare Cost and Utilization Project - Cost Analysis Reports

ncG1vNJzZmivp6x7rLHLpbCmp5%2Bnsm%2BvzqZmm6efqMFuxc6uqWarlaR8trrIrWScp6OpeqR506GcZpufqMFutc1mm6iknJa%2FtHnTqGSmmZuaeqatwqFksWWilsZuucCcn6KmlWKxprzEp5usZZ%2Bje6nAzKU%3D