The cost in dollars to make each X-ray machine is influenced by several critical factors. Understanding these variables not only helps manufacturers optimize production but also provides insights for healthcare facilities looking to invest in imaging technology. In this article, we will explore the key elements that contribute to the overall cost of X-ray machines, from materials used to technological advancements.

As healthcare technology continues to evolve, the financial implications of acquiring new equipment must be carefully considered. Every X-ray machine comes with its own set of costs, which can vary significantly based on its features and capabilities. By dissecting the factors influencing these costs, we aim to arm stakeholders with the information required to make informed decisions.

Moreover, the demand for efficient and high-quality diagnostic imaging has skyrocketed in recent years. This surge has prompted manufacturers to innovate and enhance their offerings, thereby affecting the cost structure of X-ray machines. Let's delve into the various factors that determine the financial outlay for producing X-ray machines.

Table of Contents

Factors Influencing Cost

The cost of X-ray machines is affected by multiple dimensions, including:

- Type of technology used

- Manufacturing process

- Geographical location of production

- Regulatory compliance costs

- Supply chain dynamics

Type of Technology Used

Modern X-ray machines can incorporate advanced technologies such as digital imaging, fluoroscopy, and portable systems. Each technology has its cost implications:

- Digital X-ray machines often have higher upfront costs due to advanced sensors and software.

- Portable X-ray devices offer flexibility but may use less expensive materials, impacting durability.

Manufacturing Process

The manufacturing process plays a significant role in determining costs:

- Automated manufacturing systems tend to reduce labor costs but require significant initial investment.

- Custom-built machines for specific medical applications can significantly increase costs.

Types of X-Ray Machines

Understanding the different types of X-ray machines is essential for understanding their costs. Common types include:

- Conventional X-ray machines

- Computed Tomography (CT) machines

- Fluoroscopy machines

- Portable X-ray machines

Conventional X-ray Machines

These machines are typically less expensive than their digital counterparts, but the costs can vary based on features and capabilities.

Computed Tomography (CT) Machines

CT machines are higher in cost due to their complex technology and advanced imaging capabilities.

Materials and Manufacturing

The choice of materials significantly impacts the overall cost. High-quality components, such as lead shields and digital sensors, contribute to increased expenses. Additionally:

- Bulk purchasing agreements can reduce costs.

- Local sourcing of materials can decrease shipping costs but may affect quality.

Technology and Innovation

Investments in new technologies can lead to substantial cost differences:

- Artificial intelligence integration for image analysis can increase initial costs but reduce long-term operational expenses.

- Upgrades and updates in software can lead to additional ongoing costs.

Market Demand and Pricing

Market dynamics play a crucial role in pricing strategies:

- High demand for advanced imaging can lead to increased prices.

- Competition among manufacturers can drive prices down.

Understanding market trends helps stakeholders gauge when to invest in new equipment.

Operating Costs

Beyond the initial purchase price, operating costs must also be considered:

- Maintenance costs can add up, especially for high-tech machines.

- Training staff to use advanced features can incur additional expenses.

Case Studies

To illustrate the impact of these factors, let's explore a couple of case studies:

- **Case Study 1**: A hospital investing in digital X-ray technology saw initial costs rise but benefited from increased diagnostic accuracy and lower long-term operational costs.

- **Case Study 2**: A clinic purchasing a portable X-ray machine faced lower upfront costs but had to manage ongoing maintenance expenses due to its frequent use.

Conclusion

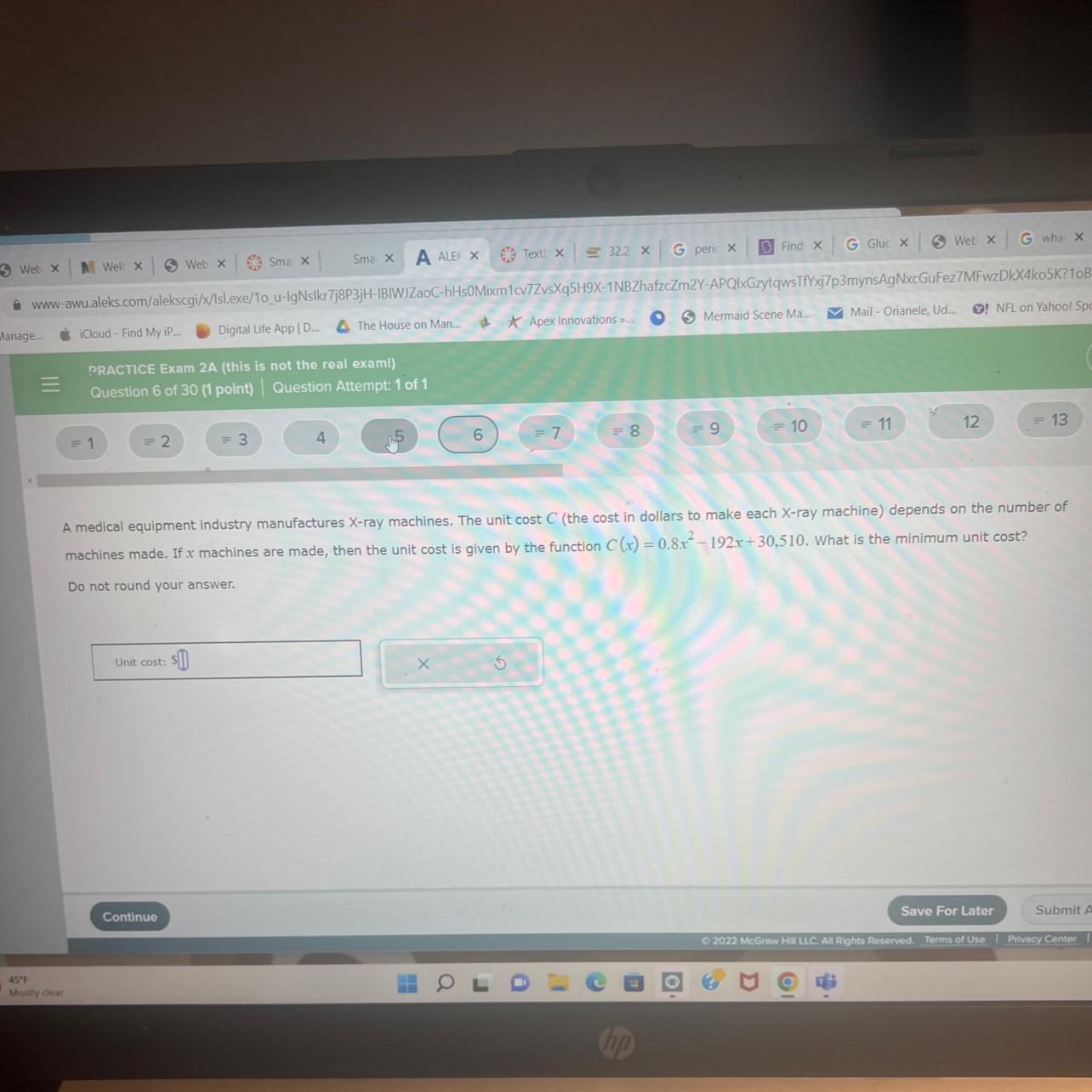

In summary, the cost in dollars to make each X-ray machine depends on various factors including technology, materials, manufacturing processes, and market dynamics. Understanding these elements can help healthcare facilities make informed purchasing decisions that align with their budget and operational needs.

We encourage you to leave your thoughts in the comments below, share this article with colleagues, or explore other related articles on our site for more insights.

Penutup

Thank you for reading our comprehensive guide on the factors that influence the cost of X-ray machines. We hope you found this information valuable and look forward to seeing you return for more expert insights in the future!

ncG1vNJzZmivp6x7rLHLpbCmp5%2Bnsm%2BvzqZmm6efqMFuxc6uqWarlaR8tbTEZpqoq6Ritq95w6ijpZmiqHq1u4ymmKSdXZqupLSMsWSrmaliuqKvx6KlnmWUmr2musOsZKimXam1pnnNrqSbnaJivKd6x62kpQ%3D%3D