The Economic Order Quantity (EOQ) model is a crucial concept in inventory management, helping businesses optimize their ordering processes and minimize costs. As companies strive for efficiency, understanding the implications of a decrease in ordering costs can lead to significant benefits. This article will delve into the EOQ model, exploring its importance, how a decrease in ordering costs affects inventory management, and the broader implications for businesses.

In today’s competitive market, businesses must constantly seek ways to reduce costs and improve operational efficiency. The EOQ model offers a systematic approach to inventory management, allowing companies to determine the optimal order quantity that minimizes total inventory costs. With a focus on the decrease in ordering costs, this article will provide insights into how organizations can leverage the EOQ model to enhance their financial performance.

Additionally, we will analyze various factors influencing the EOQ model, including demand variability, holding costs, and the impact of technology on inventory management. By the end of this article, readers will have a comprehensive understanding of the EOQ model and how a decrease in the cost of ordering can influence business operations.

Table of Contents

What is the Economic Order Quantity (EOQ)?

The Economic Order Quantity (EOQ) is a formula used by companies to determine the optimal order quantity that minimizes total inventory costs. These costs include ordering costs, holding costs, and stockout costs. The EOQ model was developed to help businesses manage their inventory levels efficiently and ensure that they are not overstocking or understocking their products.

At its core, the EOQ model is designed to answer the following questions:

- How much inventory should a company order to minimize costs?

- When should a company place its orders to ensure timely replenishment?

Key Components of EOQ

Several key components are integral to the EOQ model:

- Demand Rate: The rate at which inventory is consumed.

- Ordering Cost: The costs associated with placing and receiving orders.

- Holding Cost: The costs related to storing inventory.

Importance of the EOQ Model in Inventory Management

The EOQ model plays a vital role in inventory management by helping businesses achieve optimal inventory levels. Its importance can be summarized as follows:

- Cost Reduction: By calculating the optimal order quantity, businesses can minimize their total inventory costs, including ordering and holding costs.

- Improved Cash Flow: Efficient inventory management leads to better cash flow management, allowing businesses to allocate resources more effectively.

- Enhanced Customer Satisfaction: Maintaining optimal inventory levels ensures that products are available when customers need them, leading to improved satisfaction and loyalty.

Factors Affecting the EOQ Model

Several factors can influence the effectiveness of the EOQ model:

1. Demand Variability

Demand variability refers to fluctuations in customer demand for products. A stable demand allows for more accurate EOQ calculations, while erratic demand can lead to overstocking or stockouts.

2. Holding Costs

Holding costs include storage fees, insurance, and obsolescence costs. An increase in holding costs can lead to a higher EOQ, as businesses will need to order less frequently to minimize costs.

3. Ordering Costs

Ordering costs encompass the expenses associated with placing orders. A decrease in ordering costs will directly affect the EOQ, allowing businesses to order larger quantities more frequently.

A Decrease in the Cost of Ordering

A decrease in the cost of ordering can significantly impact the EOQ model. This reduction can occur due to various reasons, such as improved supplier relationships, advancements in technology, or increased order sizes.

When ordering costs decrease, the EOQ formula suggests that businesses can afford to order larger quantities more frequently. This shift can lead to several benefits:

- Reduced Total Costs: Lower ordering costs mean that businesses can minimize total inventory costs by ordering more efficiently.

- Increased Inventory Turnover: Larger order quantities can lead to faster inventory turnover, reducing the risk of holding obsolete stock.

- Enhanced Supplier Relationships: Ordering larger quantities can foster better relationships with suppliers, potentially leading to discounts and better terms.

Calculating EOQ

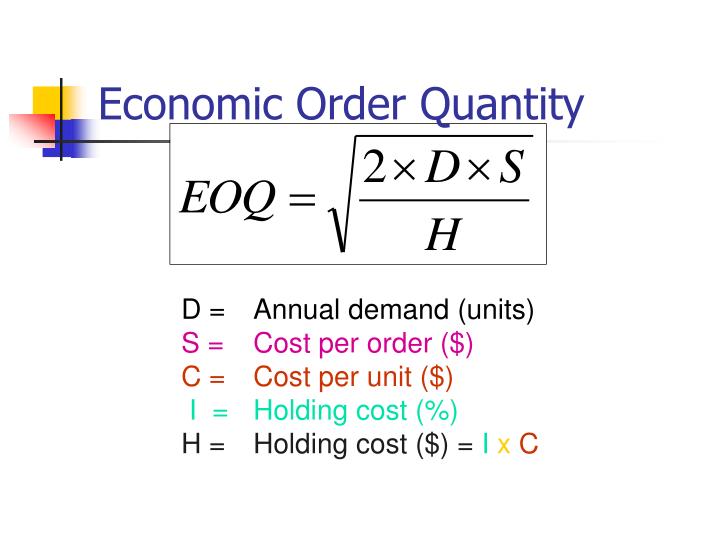

The EOQ formula is straightforward and can be calculated using the following equation:

EOQ = √((2DS) / H)

- D: Annual demand for the product

- S: Ordering cost per order

- H: Holding cost per unit per year

By using this formula, businesses can determine the optimal order quantity that minimizes total inventory costs, especially when ordering costs decrease.

Real-World Applications of EOQ

The EOQ model is widely used across various industries, including retail, manufacturing, and e-commerce. Some real-world applications include:

- Retail Stores: Retailers use the EOQ model to manage stock levels and ensure product availability while minimizing costs.

- Manufacturing Companies: Manufacturers apply the EOQ model to optimize raw material orders and reduce production costs.

- E-commerce Businesses: E-commerce platforms utilize EOQ to manage inventory levels and streamline order fulfillment processes.

Challenges in Implementing the EOQ Model

While the EOQ model offers significant benefits, there are challenges to consider:

- Data Accuracy: Accurate data on demand, ordering, and holding costs is crucial for effective EOQ calculations.

- Market Fluctuations: Changes in market demand or supply chain disruptions can impact the reliability of the EOQ model.

- Technology Integration: Implementing the EOQ model may require advanced inventory management systems, which can be costly and complex.

Conclusion

In conclusion, the Economic Order Quantity (EOQ) model is an essential tool for businesses aiming to optimize their inventory management processes. A decrease in the cost of ordering can significantly enhance the effectiveness of the EOQ model, leading to reduced total costs, improved cash flow, and increased customer satisfaction. However, businesses must also be aware of the challenges involved in implementing the model and ensure they have accurate data and technology in place.

We encourage readers to share their thoughts on the EOQ model and its applications in the comments below. Feel free to explore other articles on our site for more insights into inventory management and business optimization.

Thank you for reading, and we look forward to seeing you back on our site for more valuable content!

ncG1vNJzZmivp6x7rLHLpbCmp5%2Bnsm%2BvzqZmm6efqMFuxc6uqWarlaR8tbTEZpycp56kuqqvjKipnZ2iYr62rc2toK2xXZq8snnMqJuepF2WeqWxwqucmquVYravedOhnGabn6jBbrvFZqarnJWntq%2BzjaGrpqQ%3D